Loss of the washeteria in the Yukon-Kuskokwim village of Tuluksak on January 16, 2021, due to fire. This facility housed the water treatment and distribution pumping system.

Safe water is a fundamental human need and a primary focus of Rotary projects around the world. Many Alaskan communities remain highly vulnerable to sudden loss of community-safe water supplies. Over the winter of 2020‐2021 six remote Alaska communities, mostly Alaskan Native villages, lost their only safe water sources due to fire and other sudden casualty losses.

Rotary District 5010 responded by developing an economical, technically sophisticated but simple to deploy and operate, self‐contained emergency water system. This system can produce 7,000 gallons per day (GPD) of potable water that meets USEPA standards and can be powered by a small gasoline-powered electric generator. Two designs were developed, one that can be quickly deployed by helicopter and a second that can be rapidly disassembled to fit inside a Cessna 208 Caravan fixed wing cargo aircraft.

The design team included Jon Dufendach of CampWater Industries, LLC (CWI) in Delta Junction, Alaska, and Rotarian Mike Pollen of NTL Alaska, Inc. (NTL) in Fairbanks, Alaska. CWI designs and manufactures small potable water treatment systems for use in remote applications throughout Alaska, in Columbia, South America, and Kenya, Africa. NTL is a water and wastewater consulting, testing, and operator training company that has both Alaskan and international experience in water and sanitation. CWI and NTL collaborated on a design that would provide for the treatment of clear water drawn from beneath an ice-covered lake or river under winter conditions. To validate the design, a proof-of-concept test was performed on water pumped from the Tanana River near Delta Junction in April of 2021. A 2-GPM cartridge filtration unit manufactured by CWI was used in the test. The filtered water was disinfected with chlorine and met potable water standards in both field and certified lab tests.

Jon Dufendach (left) and Captain Mike Chiesa of the Alaska State Defense Force assemble the proof-of-concept test apparatus at the Tanana River on April 21, 2021

The proof-of-concept test validated the use of a two-stage cartridge filter system and an automated chlorination system that would meet the USEPA national standards for treatment of surface water to potable standards. A full-scale rotary-wing transportable (RWT) prototype unit was then assembled at the CWI manufacturing facility in Delta Junction. A key element of the design was to have the unit light enough to be able to be transported by a Hughes 500 helicopter, which is widely used throughout Alaska in the mineral exploration and oil and gas industries.

Rotary District 5010 provided $25,000 to CWI to procure components for the prototype unit. Additional funding was provided throughout the project by Rotary Clubs throughout District 5010 (Alaska). All the design and performance testing services were donated in-kind by CWI, NTL, and the Pollen Environmental, LLC (PE) certified potable water laboratory in Fairbanks.

The assembled prototype including a rigid aluminum frame and aircraft tensioning cables that would allow it to be lifted on a tether and transported by helicopter. The prototype unit was successfully test flown by Aurora Aviation in Delta Junction on July 8, 2021. Owner and pilot Keith Warren donated the flight services in-kind to the project.

First assembled prototype without the insulated cover, ready for test flight with a Hughes 500 helicopter by Aurora Aviation in Delta Junction on July 8, 2021.

CWI than transported the RWT prototype to Custom Canvas in Fairbanks, Alaska, where a three-ply, insulated, weather-proof cover was manufactured. The cover has an insulative “r” value of 6 allowing it to be heated by a small internal electric heater. Water is supplied to the unit using a submersible pump inserted through a hole drilled in the ice. The raw water transmission hose is an arctic-insulated, flexible design, equipped with electric heat tracing to keep the line thawed in extreme sub-zero temperatures. Two 50-foot lengths of the hose and a submersible turbine pump are supplied with the unit and included in the weight loading for helicopter transport. The arctic-grade heat-traced hose was supplied by a manufacturer in Fairbanks.

The insulated unit was transported back to Delta Junction by CWI for a second test flight series, this time with the cover on. Aurora Aviation again successfully flew the unit with one of their Hughes 500 helicopters. At the end of the test, the pilot set the RWT unit directly onto the truck trailer with the helicopter. This test demonstrated that the unit could be flown with the insulative cover on, thus allowing for more rapid deployment in an emergency.

Jon Dufendach, Mike Pollen, and Tanana Chiefs Conference USPS Officer Bill Justice with the insulated RWT unit at Custom Canvas in Fairbanks, Alaska, on July 30, 2021.

The covered prototype unit was successfully flown twice by Aurora Aviation in Delta Junction on August 5, 2021. The unit was fully loaded with the pump and hoses for the test.

Full-scale pilot tests were then successfully performed treating clear lake water in Fairbanks and in Wasilla. Numerous visitors from the Alaska Department of Environmental Conservation (ADEC), Alaska Native Tribal Health Consortiums (ANTHC), the Denali Commission, and Rotary attended the pilot tests.

Mike Pollen tests water treated by the RWT unit at Tanana Lakes on August 9, 2021.

Performance test at Seymour Lake in Wasilla, September 7-8, 2021.

A portable “STREAM” chlorine generator was used for the two lake tests. This device produces sodium hypochlorite disinfectant from table salt, water, and electricity, so hazardous chlorine (oxidizer) solutions or dry chemicals do not have to be flown to the site.

“STREAM” sodium hypochlorite generator in use at the Tanana Lakes pilot test.

The summer tests resulted in an upgrade of the filtration system to include two parallel cartridge filters in the second stage to extend the length of the filter run before the cartridges must be changed out. Under the original winter condition design, foulants such as algae and other surface water microbiology would not be expected to shorten the filter run. By increasing the capacity of the filtration system, the useful range of seasonal operation could be extended into summer months if a clear water lake or stream is available. The unit is not designed to remove heavy silt from glacier-fed streams and rivers, however.

During the pilot test in Wasilla, a full electric load test was performed at night with the water pump, electric heater and lights in the unit, heat tracing in the hoses, and the electric control panel all fully operating. A portable 7.5-kW generator successfully ran the fully loaded system. The design allows for village-supplied electric cables or an emergency generator to be used to power the unit. Electric generation capacity is not provided with the unit so it must be provided by the village or the emergency response team. Emergency electric generators are widely available so that component is left to the response team to provide.

During the performance tests, monitoring was provided by NTL. On site tests for turbidity (particulates in water), chlorine residual, pH, and temperature were performed. These tests are required by the USEPA and ADEC for properly treating surface water to potable water standards. Both the onsite tests and additional certified laboratory microbiological and chemical tests demonstrated the system produced potable water in each of the performance tests.

Representatives from ANTHC requested that the design team consider the development of a version that could be transported in a Cessna 208 Caravan cargo plane, which is widely used throughout Alaska for village transport. Jon Dufendach developed a design that could be rapidly disassembled into four sections that would each fit inside the cargo hold of a Caravan. CWI completed the assembly of a prototype by the end of 2021 and transported it to Fairbanks to demonstrate loading in a Caravan aircraft. The unit was successfully loaded in a Caravan at Wright’s Air Service in Fairbanks, validating the design.

Fully assembled Fixed-Wing Transportable (FWT) emergency water plant at CampWater Industries, LLC manufacturing facility in Delta Junction on February 28, 2022.

The FWT modules were assembled as two units with an interconnecting insulated sleeve. One unit houses the filtration and chlorination equipment and the control panel, and the second unit houses a 165-gallon potable water storage tank, delivery pump, and filling station. Both the FWT and RWT designs include a fill station inside an insulated box that is accessible from the outside of the unit. A tap is provided for individuals to quickly fill water containers (e.g.: 5-gallon water jugs) and a Cam-LockÒ fitting to connect to a larger potable water delivery hose to fill a water tank in a pickup truck. The Cam-LockÒ fitting can also be connected to an insulated hose to fill a larger storage tank in the village if available. This would allow the village water distribution system pumps to be used if they were still operational. Under that condition, the output of the water treatment unit is nearly doubled.

View of the water fill station outside the RWT unit. The water jug filling tap is on the left and the truck filling hose is on the right. The controls on the top turn the pump on or off.

The final test of both designs was a full performance test under winter conditions in Delta Junction. Both units were powered up on February 28, 2022, and left overnight in temperatures that reached 0 °F. The submersible pump was also left in place beneath 32 inches of ice.

Jon Dufendach and Mike Pollen at the winter performance test site at the Whitestone Farms gravel pit, Delta Junction, Alaska, February 28, 2022.

Both units were operated on March 1, 2022, producing potable quality water in ambient temperatures that reached 14 °F during midday. Representatives from the Tanana Chiefs Conference in Fairbanks and the Denali Commission assisted with the successful performance test. An additional cold weather test was performed by CWI over a two-day period from March 13 to 15, 2022. The units remained fully operational at temperatures that reached -20 °F. During that test, the heater in one unit was shut down for two hours at a temperature of -5 °F and then turned back on. The unit was still fully operational, demonstrating the efficacy of the insulative cover system.

Three of the RWT units and the one FWT prototype unit were completed. Funding for the project included the initial $25,000 from Rotary D5010 Alaska and an additional $31,000 donated by Alaskan Rotary Clubs. Over $131,000 was donated as in-kind services for the design, testing, and user training (CWI, NTL, PE), flight services (Aurora Aviation), development of memorandums of agreement for transfer of ownership (Kashi Law Offices), and for transportation of the completed units to Bethel and Nome (Alaska Marine Lines). The Denali Commission provided a $177,000 grant for the construction of two of the RWT units and the FWT prototype. The final project cost totaled over $357,000, with the project being completed in 18 months from concept to delivery.

The three RWT units were gifted to the Norton Sound Regional Health Corporation (ANTHC) in Nome, the Alaska State Defense Force (ASDF) in Bethel, and ASDF for a unit positioned at the Alaska National Guard Armory in Wasilla. ASDF has offered to provide emergency transport services using either Black Hawk or Chinook helicopters operated by the Alaska Air National Guard. The FWT unit was gifted to the Tanana Chiefs Conference (ANTHC) in Fairbanks, which has the largest service region in Alaska and had requested the FWT design.

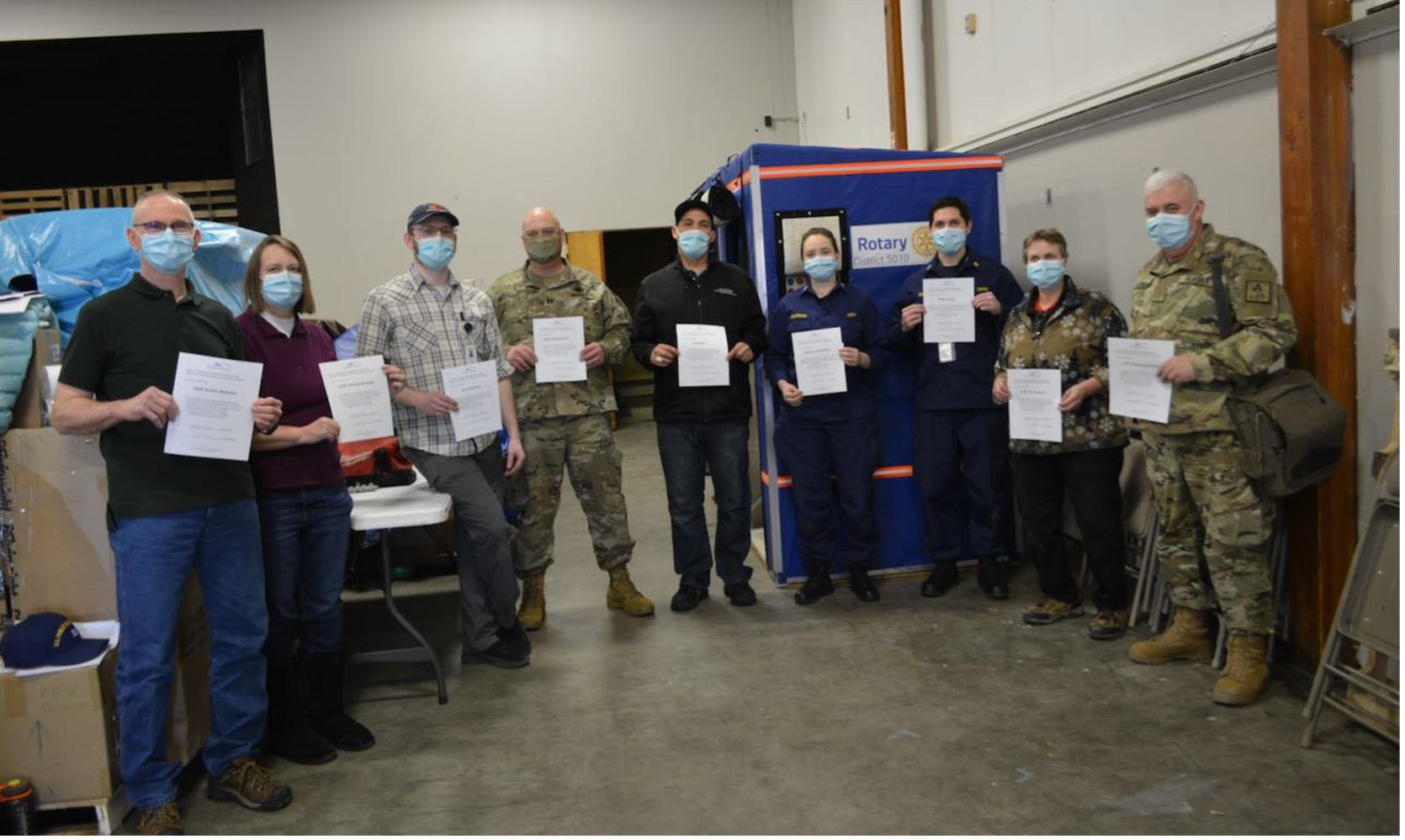

TCC and ASDF staff with training completion certificates in Fairbanks on April 22, 2022.

CWI and NTL provided training services for the end users in Fairbanks and Anchorage, and CWI later provided training services for the ASDF and ANTHC water operators in Wasilla and Bethel. The units are fully operational and available to be deployed throughout Alaska.

Left to right: ASDF Commanding General Simon Brown, Alaska Governor Mike Dunleavy, Jon Dufendach of CampWater Industries, LLC, Chief Warrant Officer (USCG) Hamilton Long, and Major Mike Chiesa (ASDF) at the Bethel Armory after completion of system operational training for ASDF and ANTHC personnel by Jon Dufendach.

CWI is continuing its development of emergency water systems as a commercial product. They are currently working on a version that is equipped with a seawater desalination system that could be deployed with the US Coast Guard.

“Understanding Water”